Undercounter warewashers improve efficiencies and speed of service; however, operators can face challenges when using these units.

High-temp machines can emit hot steam when opened immediately after completion of the wash/rinse cycle. That’s not just uncomfortable for operators, it also makes it difficult to remove glassware that is hot and wet.

Now there is an alternative that takes care of these issues and more. The new M-iClean U with ComfortAir™ technology from Meiko is an undercounter machine that generates up to 80% less steam, significantly reducing both steam and heat when the door is opened right after the cleaning cycle.

“It promotes flash drying of ware, so there are benefits on so many different levels,” says Steve Grahs, regional vice president at Meiko.

Uniquely Engineered

Meiko’s new M-iClean U with ComfortAir™ technology features a new heat-recovery system design. It condenses even more steam on the internal wall of the machine as opposed to using a heat-exchanger device in the back. By the end of the wash cycle, there’s virtually no moisture. Once it’s condensed and absorbed, the machine then reuses it as an efficient water heating source. Because the machine’s walls are cooled through a condensation effect, each wash saves time, energy and money — and with less steam the kitchen environment remains cooler.

“Our baffle heat recovery system is maintenance free,” Grahs explains. “Dishes and glassware come out perfectly clean, with a speedy drying process.”

A larger heat recovery tank moves more water, saving energy. M-iClean U with ComfortAir™ also eradicates the SARS-CoV-2 virus in just one wash cycle.

With less moisture left in the machine, there’s virtually no need to hand dry. In fact, results show a 98% reduction of moisture on plates and 75% reduction on glassware. And the heating time is expedited, so M-iClean U with ComfortAir™ saves 21% on operating costs.

Thoughtful & Intuitive Features

Meiko’s new M-iClean U with ComfortAir™ offers a number of basic features that simplify use and increase efficiency.

“It has an integrated, yet robust wash and rinse arm designed to spin as one, with a dual filtration of the wash water, so no debris gets caught in the jets during the cycle,” Grahs says.

“It has an integrated, yet robust wash and rinse arm designed to spin as one, with a dual filtration of the wash water, so no debris gets caught in the jets during the cycle,” Grahs says.

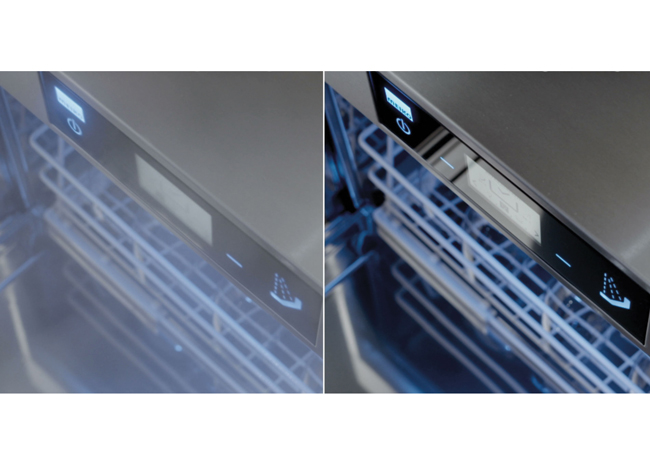

Blue-colored touch points provide guidance for the components that need to be removed for daily cleaning and maintenance. In addition, the chemical pumps and stainless steel tubing are integrated into the machine, which takes the place of separate dispensing systems that need to be wall mounted.

The warewasher also features user diagnostics or built-in messaging, which communicates the wash cycle stage at a glance.

“These machines are very intuitive for monitoring component sensors, diagnostics and viewing troubleshooting tips to identify issues and get the machine back in operation as quickly as possible,” Grahs says. “And its double-wall insulation ensures quiet, cool operation.”

There are three M-iClean U models and sizes available. The M-iClean UM has an optional GiO Module reverse osmosis system that produces glasses so clean, it virtually eliminates hand-polishing.