When it comes to kitchen flooring, there is no perfect solution. There are three main types of floors and each have pros and cons. When stepping through the swinging doors that bring you behind the scenes of a restaurant, you’ll find the floor gets hit with a bit of everything that’s in the kitchen: hot grease, moisture, food byproduct and residue, harsh cleaning chemicals and more. These are all environmental factors that restaurant designers, owners and manufacturers must consider when specifying a kitchen floor, along with the initial costs and required maintenance associated with each type of flooring. Here are the three best options:

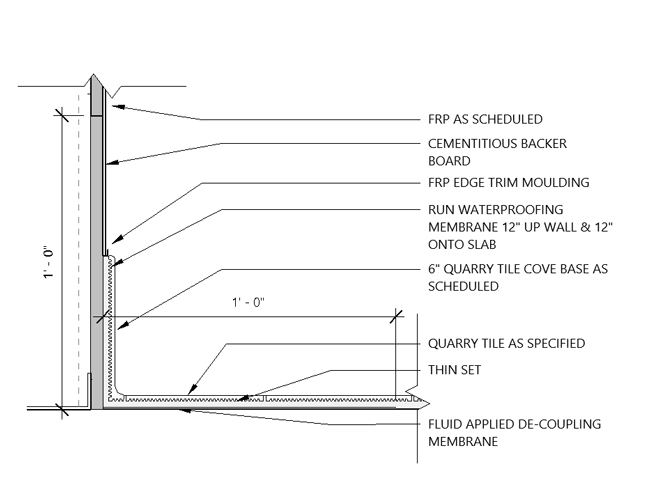

No matter the flooring selected, proper installation is a must. Here, an example of how to properly install quarry tile.

No matter the flooring selected, proper installation is a must. Here, an example of how to properly install quarry tile.

- Quarry Tile. Quarry tiling is arguably the most well-known and certainly the oldest flooring option within the restaurant industry. The tile has been around for ages and is extremely durable, making it seemingly cost-effective. However, the devil is in the details. While all grout will inevitably break down, the type of grout you choose can slow that process. We always specify an industrial epoxy grout when using quarry tile — it is the least porous grout option, so moisture, chemicals and kitchen products are less likely to penetrate it or break it down (or do so at a much slower rate). Despite being the most durable grout option, it is very brittle and can crack if installed improperly. Epoxy grout can also be more challenging to install because of its quick dry time. The other key to quality quarry tile assembly is a waterproof, antifracture membrane to ensure that the assembly is completely waterproof and does not move with the concrete subflooring. Although installing the membrane adds an extra step and fee, it is critical in extending the life of your floor.

- Polyvinyl Sheet. When done correctly, polyvinyl sheet can be the optimal choice for restaurant kitchen floors. It is typically a ¼-inch thick, hard, rubber, mat-like material that is rolled out directly onto the substrate, set with an adhesive and welded by heat or chemicals. These welds at the seams and the integral cove base essentially create a monolithic surface when installed correctly. The sheet material is nonporous, which makes it practically impenetrable and essentially chemical and byproduct resistant. The material is also usually made with recycled content and has antifatigue cushioning, making it ergonomic. This is particularly important in environments where you have employees working on their feet for long hours, such as a restaurant. Its elasticity allows it to move with the natural dynamics of the subfloor beneath it and makes it much less likely to crack than a less elastic option. However, it does have a very low heat tolerance and will melt if you place extremely hot kitchen equipment on it.

Although polyvinyl can be installed relatively quickly, the chemical welding must be done correctly to prevent breakdown and sheet separation. You also must ensure that the sheets are being applied to a concrete subfloor that has had adequate time to cure. If there is too much moisture in the concrete, it will continue trying to release that moisture and create a hydrostatic pressure that can cause the seams to split, the floor to bubble, and worse yet, mold to grow under the sheet vinyl. - Poured Resinous Urethane Flooring. There are many types of poured or troweled resinous floors on the market. While some are even touted as appropriate kitchen flooring (like methyl.) methacrylate and epoxy), urethane is by far the most appropriate resinous floor option for a commercial kitchen. Urethane flooring is a seamless flooring system that is extremely elastic. The material is poured directly onto the substrate and bonds to it without any adhesive (almost like a skin to the substrate). Its durability and elasticity make it less likely to crack from typical settlement or building movements, and it is chemical, moisture, heat and slip resistant. While you don’t have to worry about moisture emitting beneath the surface or grout-related issues, urethane flooring doesn’t have the cushion that polyvinyl has and can’t be spot-patched as easily as quarry tiling because you have to cut out a larger section.

No matter which of these three flooring options you choose, there are two additional factors to keep in mind: quality installation and proper maintenance. We discussed the many challenges with installation for each floor option, but each one also has a unique set of cleaning and maintenance requirements. The easiest way to get the most out of a commercial kitchen floor and ensure that it lasts as long as possible is to use the manufacturers’ recommended cleaning products and processes. I can’t count how many times I’ve seen a kitchen floor improperly mopped and cleaned in my almost 30-year career. The cheapest or most caustic cleaner is rarely the best. Each of these flooring options requires a cleaner with a specific pH to ensure that grease is being removed without the flooring being chemically damaged. A clean water rinse and squeegee technique is also highly recommended after any industrial floor cleaner is used to ensure that you get all the grease and dirt off the floor and down the drains. These simple steps will help prolong the life of all three of these flooring options.

Interested in learning more about flooring?

Steve Starr, president of starrdesign in Charlotte, N.C., is a nationally recognized leader in restaurant and retail design. While his insight and expertise span the hospitality industry, his focus is on branding, consumer behavior and the development process.

Do you have a problem? Would you like three solutions? This email address is being protected from spambots. You need JavaScript enabled to view it..